our current and old client

our certification

Tubular & Drilling Tool Inspection Services

We offer complete inspection services for tubulars and drilling tools based on API RP 7G-2 and DS-1 standards. These include visual examinations, non-destructive testing (NDT), and integrity assessments to detect wear, corrosion, and cracks. Our inspection process also features tool classification, detailed reporting, and traceability, ensuring your drilling assets maintain operational safety and performance throughout their service life.

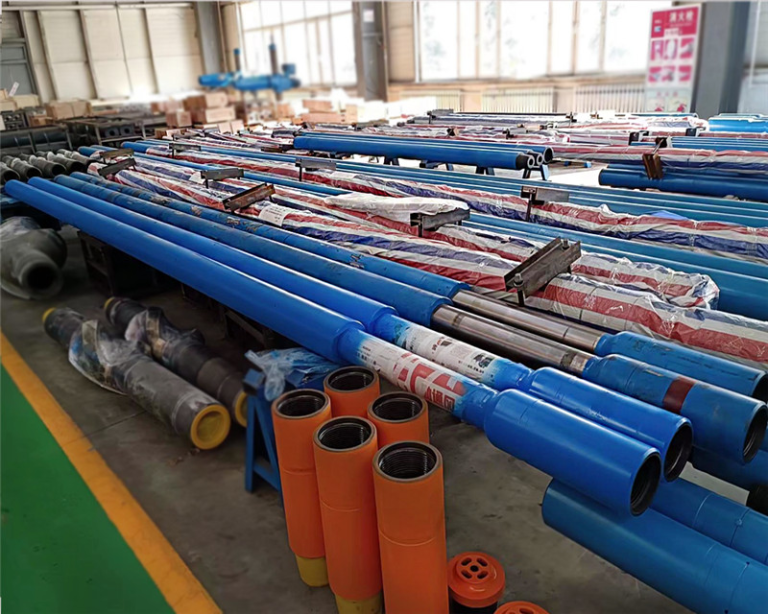

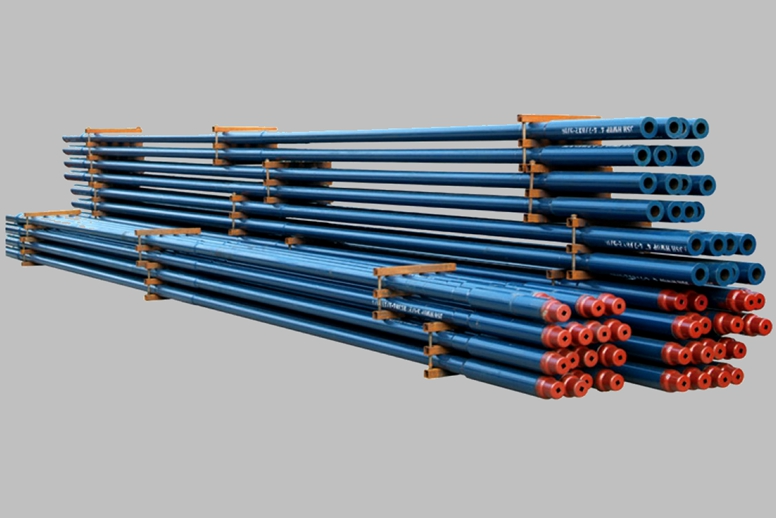

Rental Tools Drilling

Our rental services provide a wide selection of drilling tools such as drill collars, drill pipes, mud motors, jars, and stabilizers—ready for rapid deployment to suit temporary or specialized projects. All rental equipment undergoes rigorous inspection and preparation before delivery to ensure field readiness. This service is ideal for reducing capital expenditure and accelerating the startup of drilling operations.

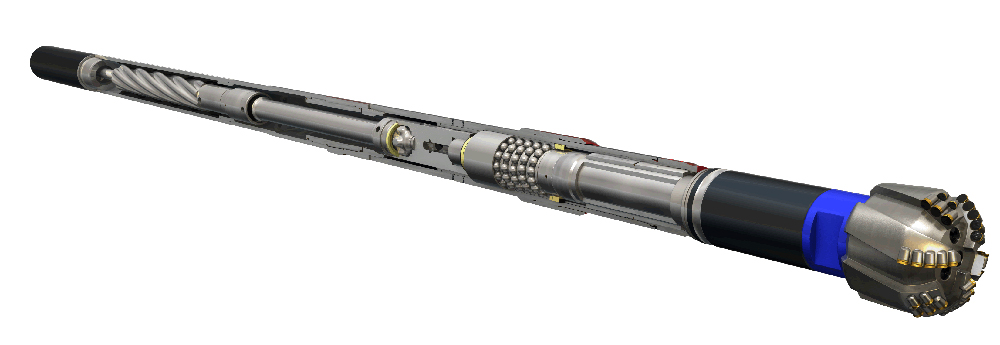

Mud Motor

Mud motors are crucial in directional drilling, converting hydraulic pressure from drilling fluid into mechanical rotation to drive the bit. This allows for precise control of the bit direction without rotating the entire drill string. Our high-performance mud motors are available in various sizes and configurations, suitable for complex formations and high-precision drilling paths. They improve efficiency and reduce mechanical stress on equipment.

Drilling Jar

A drilling jar is an essential tool for dealing with stuck pipe situations, delivering powerful axial impacts to help release the drill string. Depending on the design—mechanical or hydraulic—it can generate upward or downward forces without halting operations. Proper use of a jar reduces downtime and prevents costly fishing operations. We provide a range of jars optimized for different well conditions and loads.

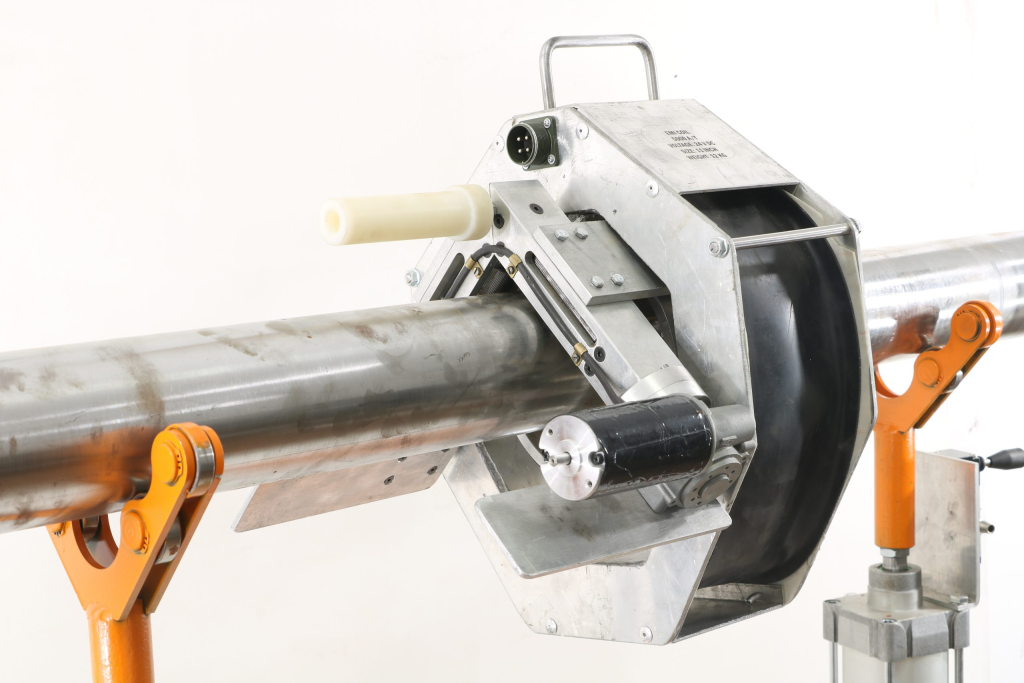

Electro Magnetic Inspection (EMI)

EMI (Electro Magnetic Inspection) is a high-precision, non-destructive testing technique used to detect longitudinal and transverse flaws in tubular bodies and drill string components. It works by inducing a magnetic field and analyzing disturbances caused by defects on or below the surface. EMI plays a vital role in preventive maintenance, asset integrity management, and ensuring operational safety in the field.

Heavy Weight Drill Pipe (HWDP)

Heavy Weight Drill Pipe bridges the gap between standard drill pipe and drill collars, providing additional weight-on-bit while offering greater flexibility and fatigue resistance. HWDP reduces string buckling and improves load distribution in directional and horizontal drilling. Designed to withstand high torque and stress, it extends the life of the drill string in challenging drilling environments.

Non-magnetic Drilling Collar

Non-magnetic drill collars are used in combination with MWD and LWD tools to prevent magnetic interference and ensure accurate directional measurements. Made from specialized alloys like Monel, these collars offer high strength, corrosion resistance, and low magnetic permeability. They are essential for critical wells requiring precise geosteering and real-time downhole data acquisition.

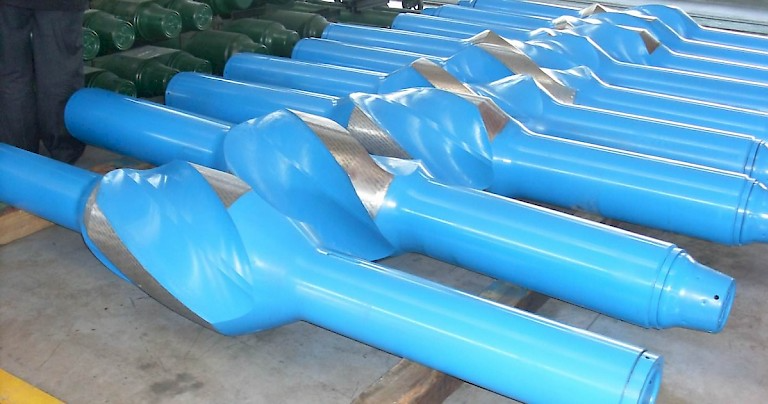

Drilling String Stabilizer

Drill string stabilizers are used to minimize vibration, reduce hole deviation, and improve drilling accuracy. Strategically placed along the BHA, they help maintain toolface stability and reduce wear on both the bit and downhole tools. We offer a variety of stabilizer designs—straight-blade, spiral, and sleeve-type—tailored to specific formation conditions and well profiles.

Drilling Near Bit Stabilizer

Near-bit stabilizers are installed just above the drill bit to improve bit control and directional responsiveness. By stabilizing the lower part of the BHA, they enhance trajectory control in high-precision directional drilling operations. These tools are especially valuable in complex well paths such as sidetracks and horizontal sections, where consistent directional behavior is critical.

Circulation Sub (PBL)

The PBL circulation sub is a downhole tool that enables the re-establishment of circulation without pulling out the drill string. It’s activated from the surface and used during cementing, hole cleaning, or pressure control operations. This tool significantly enhances operational efficiency, reduces non-productive time, and improves wellbore cleaning by enabling high flow rates when needed.

Gyro Survey

Our Gyro Survey services utilize advanced gyroscopic instruments to determine wellbore trajectory with high precision, independent of magnetic fields. This method is especially effective in environments with magnetic interference such as near metallic structures or iron-rich formations. It provides accurate measurements of inclination and azimuth, essential for geosteering and complex well planning. Gyro surveying plays a critical role in directional, horizontal, and multilateral drilling operations.

07644468321

07644468322

Marketing@nddkcompany.ir

Created by NDDK IT

2010-2025